‘Replenishment‘ is the term used to describe the processes of ‘restoring’ or ‘filling’ an inventory item’s stock position to the level required to be able to satisfy on-going demand. We use the term in Online Advantage to cover the functionality provided in the system to assist in the management of the inventory position of each product to best meet the future on-going demand for the item.

Depending on your requirements, there are three levels of replenishment settings available:

- ‘Default’ Replenishment settings which are applied globally

- Stock Location settings for the ‘default’ replenishment behaviour for inventory items within each stock location (warehouse)

- Inventory Master settings where the lowest level of behaviour can be established for individual inventory items

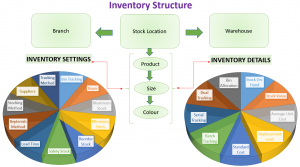

Whilst the first two levels offer a quick way to get up and running, typically it is at the 3rd level, the individual inventory item level, where the detailed management of replenishment occurs.  At this inventory level, information such as stock quantity details (e.g. on-hand, on-order, committed, available etc.), stock values (average, standard, replacement costs) and the approach to replenishment for the item are stored and maintained.

At this inventory level, information such as stock quantity details (e.g. on-hand, on-order, committed, available etc.), stock values (average, standard, replacement costs) and the approach to replenishment for the item are stored and maintained.

To get a better view of the details available at the Inventory level, please refer to the schematic provided.

Regardless of where the settings originate from, the most significant setting for an item is its ‘Replenishment Type’. The replenishment type determines the default method used to ‘fill’ or ‘re-fill’ the item. When an item’s replenishment type is set, there are three other important replenishment settings established at the same time:

- Stocking Method

- Replenishment Method

- Replenishment Mode

It is the combination of these settings that determines all the replenishment actions the system takes when it determines that an individual inventory item has reached a point where replenishment “action” is required.

Below is a summary of the options available for the four replenishment settings:

Replenishment Types

- Outside Supplier – indicates that the item is purchased from an external vendor (supplier) with the following default settings:

- Stocking Method = ‘Stocked’

- Replenishment Method = ‘Purchase Order’

- Replenishment Mode = ‘Manual Order’

- Manual Work Order – indicates that replenishment for the item is via a manual ‘internal’ Manufacturing process with the following default settings:

- Stocking Method = ‘Stocked’

- Replenishment Method = ‘Work Order’

- Replenishment Mode = ‘Manual Order’

- Automatic Work Order – instructs the system to automatically create work orders for the item using the internal Manufacturing system with the following default settings:

- Stocking Method = ‘Stocked’

- Replenishment Method = ‘Work Order’

- Replenishment Mode = ‘Automatic Order’

- Kit Issues – tells the system to automatically create kitting work orders for the item to satisfy individual order demand using the Manufacturing system. Kitting uses the following default settings:

- Stocking Method = ‘Kit i.e. Non-Stocked’

- Replenishment Method = ‘Work Order – Kit’

- Replenishment Mode = ‘Automatic Order’

- Manual Transfer – indicates that the method of replenishment for the inventory item is via a manual ‘internal’ stock transfer from another stock location with the following default settings:

- Stocking Method = ‘Stocked’

- Replenishment Method = ‘Transfer Order’

- Replenishment Mode = ‘Manual Order’

- Automatic Transfer – instructs the system to automatically replenish the inventory item via an ‘internal’ stock transfer from another stock location with the following default settings:

- Stocking Method = ‘Stocked’

- Replenishment Method = ‘Transfer Order’

- Replenishment Mode = ‘Automatic Order’

- Non-Stock Work Order – tells the system to give the user an interactive option to create work orders for the item using the internal Manufacturing system with the following default settings:

- Stocking Method = ‘Non-Stocked’

- Replenishment Method = ‘Work Order’

- Replenishment Mode = ‘Manual Order’

- Non-stock Purchase – sets the system to replenish the item via interactive purchase from an external supplier with the following default settings:

- Stocking Method = ‘Non-Stocked’

- Replenishment Method = ‘Purchase Order’

- Replenishment Mode = ‘Manual Order’

- No Replenishment – this tells the system that the item is not to be replenished i.e. take no action. To be used. for example, where stock is obsolete

Stocking Method

- Stocked – used to indicate that the item should always have stock available and so the system should be calculating safety levels, minimum/maximum quantities etc. in order to maintain a level of stock in the warehouse

- Non-Stocked – used for items that should not be held perpetually in the warehouse, but rather are replenished via an order when there is demand for the item

- Indent – a ‘Non-Stocked’ item that is replenished on a one to one basis i.e. the order that initiates the demand is matched and linked to a specific individual replenishment order

- Kit – a ‘Non-Stocked’ item that is replenished ‘as required’ on a one to one basis via Kitting Work Order. The system uses the items’ Manufacturing specification to determine the raw material/sub-assembly items that go to make up the finished ‘Kit’ item. The system always assumes it will use any stock available for the item before creating a Kit Work Order. The items that make up the finished Kit are assumed to be available and are automatically taken from stock via Kit Issue. The finished item is automatically receipted into stock via a Kit Receipt. The item is then issued out of stock for the order that created the original ‘demand’

- No Replenishment – this tells the system that this item is not to be replenished i.e. take no action. To be used. for example, where stock is obsolete

Replenishment Method

- Transfer Order – Stock Transfer Orders are created to move items from one Stock Location to another for the purpose of replenishment. Transfer Orders flow through the normal Order Management processes just like a Customer Sales Order

- Work Order – Manufacturing Work Orders are created to manufacture an item based on a previously established specification (Bill of Materials)

- Purchase Order – Supplier Purchase Orders are created to place replenishment orders on external suppliers. They are an ‘outside’ or ‘external’ source as opposed to the possible ‘internal’ sources of an item i.e. Stock Transfer or Work Order

Replenishment Mode

- Manual Orders – items requiring ‘Replenishment’ attention under this mode appear on the Stock Replenishment Report (available as part of overnight EOD processing and on demand via the menu). The system will in effect advise that the item(s) require a replenishment order to be raised, and a recommend re-order quantity. The report is broken into sections based on the ‘Replenishment Method’ and can optionally separate the ‘Non-Stock’ items from the ‘Stocked’ items. The Items are also listed by ‘Buyer’ and ‘Supplier’ where they are sourced externally via Purchase Order. The responsibility is then solely with the user(s) to act on these recommendations by creating Purchase Orders, Stock Transfer Orders or Work Orders

- Planned Orders – are automatically created as part of the DRP/MRP system. Planned orders are used to drive the requirements planning systems and are held in the system with a ‘planned’ order status. Once their required date reaches the “firm order” time fence they are released. These ‘released’ orders are effectively live orders similar to both ‘Manual’ or ‘Automatic’ orders

- Automatic Orders – this mode creates orders during the analysis of the inventory replenishment requirements, removing the need for manual action by users. These automatically created orders can then flow through the normal internal processes of the Purchasing, Transfer or Manufacturing systems as with any manually created order

Replenishment Re-Order Point

When an item uses the ‘Stocked’ stocking method, all the ‘Methods’ and ‘Modes’ trigger at the ‘Replenishment Re-Order Point’ i.e. the point at which an item needs to be replenished. This is the point where the items ‘Nett’ quantity falls to or below the items ‘Minimum Quantity’. This is the trigger point for the system to take an action based on the items Replenishment ‘Method’ and ‘Mode’ setting.

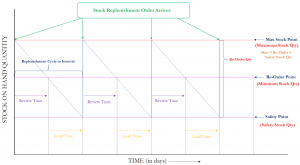

The system calculates a ‘Re-Order Quantity’ for the item at that point, which in theory would bring the item back to its ‘Maximum Quantity’ upon receipt of the replenishment order i.e. based on the ‘Lead Time’ of the item. This should then see the items Stock On Hand quantity see-saw up and down over time, effectively moving from its ‘Maximum’ quantity down to its ‘Safety-Level’ and then back-up to its ‘Maximum’ again when a replenishment order is receipted in. This schematic has been included to help show what happens.

The system calculates a ‘Re-Order Quantity’ for the item at that point, which in theory would bring the item back to its ‘Maximum Quantity’ upon receipt of the replenishment order i.e. based on the ‘Lead Time’ of the item. This should then see the items Stock On Hand quantity see-saw up and down over time, effectively moving from its ‘Maximum’ quantity down to its ‘Safety-Level’ and then back-up to its ‘Maximum’ again when a replenishment order is receipted in. This schematic has been included to help show what happens.

Note how the item’s re-order quantity is essentially the difference between the item’s ‘Safety Stock’ quantity, and its ‘Maximum’ stock quantity. You can also see that the ‘Replenishment Cycle’ for the item is basically the interval (time-frame) between replenishment orders. This means that the item’s Maximum stock is really the addition of the Safety Stock and the Re-Order quantity.

This means you can actually think about your stock holding in terms of time rather than in terms of quantity. In other words it can be described as a cycle, in days, and that the days could be used to calculate the quantities. For instance, if you decide that you always want to have 5 days worth of stock for a given item, then your Safety Stock quantity could be calculated using the historical demand of the item to determine what level 5 days would equate to. We call this period the ‘Safety Time’. It can be defined as the time you are prepared to wait for a later replenishment order to arrive without running out of an item. This time is used to cover you with stock brought about by delivery issues or due to poor stock forecasting.

In the same way, if you wanted to replenish an item every 30 days, then you could calculate the amount of stock that you needed to order every 30 days based on the historical demand of the item. We call this cycle period the ‘Review Time’. It’s the time that passes between re-ordering activities for the item. Shorter review times mean smaller order quantities, but more orders as you would be ordering more often and so handling the replenishment of the item more frequently. Shorter review times also means smaller order quantities and so means lower stock holdings, thereby reducing the cost (or value) of the stock holding of the item. Of course carrying a lower stock holding of an item increases the chance that you will not have it available to satisfy demand.

The Re-order quantity plus the Safety Stock quantity would give you the Maximum stock quantity of the item. Expressed in terms of time, the Maximum stock is the sum of the stock quantity calculated by adding the Safety Time, the Lead Time and the Review Time.

The above mechanisms exclude ‘Non-Stock’, ‘Indent’ and ‘Kitting’ approaches which work more on a one to one relationship of outgoing ‘demand’ order to incoming ‘replenishment’ order. They are essentially operating on an “action as needed” basis.